The RFID Path to Autonomous Retails and Factories: Challenges and Promises

Edwin C. Kan

School of Electrical and Computer Engineering, Cornell University, Ithaca, New York 14853, USA

Abstract

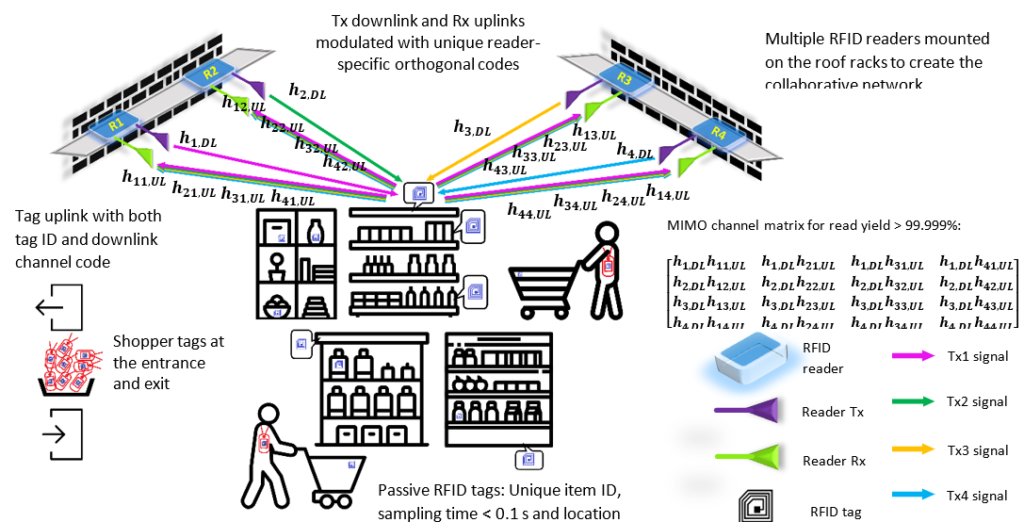

Autonomous just-walk-out retails such as Amazon Go have been presently implemented by multiple cameras, prolific bar code readers, and sensor fusion. However, facility cost scaling as well as inventory management of misplacement and thievery remain challenging. The vision-based technology also faces other difficulties such as layout obstruction and computing cost with 3D voxels. The bar-code marker is mature and low-cost, but has further view angle and range concerns. UHF (ultra-high frequency) radio-frequency identification (RFID) has been designed to serve as item-level logistics from 2005, offering both ID and locating, but the present hardware and EPC Gen 2 protocol are often restricted to the conveyor-belt system due to the low read yield (90% – 98%) and locating reliability (around 10 – 50 cm at CDF of 90%) in the complex ambient. Applications of inventory and retail however often require the read yield to be higher than 99.999% and the location tracking with 5 cm at CDF of 99%. This promise of autonomous retail and inventory has been actively pursued by RFID industry, but with limited success in the two critical numbers for ID and locating reliability. Present EPC Gen 2 has further challenges in reader-to-reader collision (R2RC) and real-time tag responses, which further disable the use of multiple RFID readers to track more than 5,000 tags simultaneously in a large facility.

The essential feature for high reliability in the any 3D inventory system is the spatial diversity of observation without significant increases in cost and sampling time. In the UHF RFID system, the myriad passive tags are diversely deployed with random antenna orientation having only limited network capabilities due to cost, and the solution has to come from the reader deployment. How can we create a cost-effective RFID system to realize autonomous retails and assembly facilities? The successful solution does promise to revolutionize the retail industry and manufacturing logistics, and serve as an important step towards the realization of the Internet of Things (IoT).

Short Bio of the Speaker

Edwin C. Kan received the B.S. degree from National Taiwan University in 1984, and the M.S. and Ph.D. degrees from the University of Illinois at Urbana-Champaign in 1988 and 1992, all in electrical engineering. From 1997, he was an Assistant Professor with the School of Electrical and Computer Engineering (ECE), Cornell University, Ithaca, NY, where he is now a Professor in the fields of ECE, Applied Math and Biomedical Engineering. His main research areas include biosensors, RF indoor locating, RFID, CMOS technologies, semiconductor devices, flash memory, and numerical methods for PDE and ODE. Dr. Kan received the Presidential Early Career Award for Scientists and Engineer (PECASE) from President Bill Clinton in October 2000. He has published over 280 journal and referred conference papers and has graduated 30 Ph.D. students. He also received several inventor and teaching awards from Cornell Universities.